What Is Curing Of Concrete?

Curing can be described as the process of maintaining a satisfactory moisture content and a favorable temperature in concrete during the period immediately following placement, so that hydration of cement may continue until the desired properties are developed to a sufficient degree to meet the requirement of service.

The curing of concrete plays a major role in developing the microstructure & pore structure of concrete. The uniform temperature should be maintained throughout the concrete depth to avoid thermal shrinkage cracks. If curing is neglected in the early period of hydration, the quality of concrete will experience a sort of irreparable loss. Efficient curing in the early period of hydration can be compared to a good and wholesome feeding given to a newborn baby.

Methods Of Curing Concrete

1- Water curing.

2- Membrane curing.

3- Application of heat.

1- Water curing

This method is by far the best method of curing as it satisfies all the requirements of curing, namely, promotion of hydration, elimination of shrinkage, and absorption of the heat of hydration. It is pointed out that even if the membrane method is adopted, a certain extent of water curing should be done before the concrete is covered with membranes. Water curing can be done in the following ways:

A- Immersion

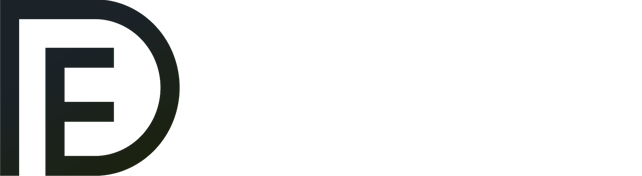

This method is commonly used in the laboratory for curing concrete test specimens. The precast concrete items are normally immersed in curing tanks for a certain duration. Pavement slabs, roof slabs, etc. are covered underwater by making small ponds. Water immersion is particularly important when the concrete has a low water-cement ratio.

B- Ponding

In the ponding method, small rectangular or square artificial ponds are built using bunds of clay or lean mortar or sand across and along the concrete surface. Water is filled in small rectangular or square ponds two or three times per day depending upon the atmospheric conditions.

C- Spraying or Fogging

Fogging and sprinkling with water are excellent methods of curing when the ambient temperature is well above freezing and the humidity is low. Fogging is applied to minimize plastic shrinkage cracking until finishing operations are complete. A vertical retaining wall or plastered surfaces or concrete columns etc. are cured by spraying water.

D- Wet Covering

The exposed surface of the concrete is prevented from drying out by covering it with hessian, canvas, or empty cement bags. These are periodically wetted. The interval of wetting will depend upon the rate of evaporation of water.

2- Membrane Curing

The process of applying a membrane-forming compound on a concrete surface is termed Membrane curing. The membrane serves as a physical barrier to prevent the loss of moisture from concrete. It’s usually used if there’s an acute shortage of water or the concrete’s placed at an inaccessible site.

The various membrane-forming compound is

- Bituminous & Asphaltic emulsion.

- Rubber latex emulsion.

- Emulsions of waxes & resins.

- Water repellent chemicals, viz. Silicon.

- Emulsions of paraffin.

- Plastic sheeting.

Note: The curing compound must be applied on concrete before all the moisture/water content evaporates to obtain the best results.

3- Application of Heat

The strength development of concrete not only depends on time but also on the temperature. Concrete is subjected to higher temperatures while the wetness is maintained to accelerate the hydration process for faster development of strength.

Following manners are adopted for applying heat:-

A- Steam curing

Steam curing is used for precast concrete members. The members are heated up by steam either at high pressure or low pressure. Live steam, heating coils, electrically heated pads, or forms are used for steam curing.

B- Curing by Infrared radiations

This system is adopted in very cold climatic regions.

C- Electrical curing

Concrete can be cured electrically by passing an alternating current through the concrete itself between two electrodes either buried in or applied to the surface of the concrete.

Click Here To See 19 Technical Terms About Reinforcement A Construction Supervisor Should Know